Home > Product > Electrically Insulated Bearings

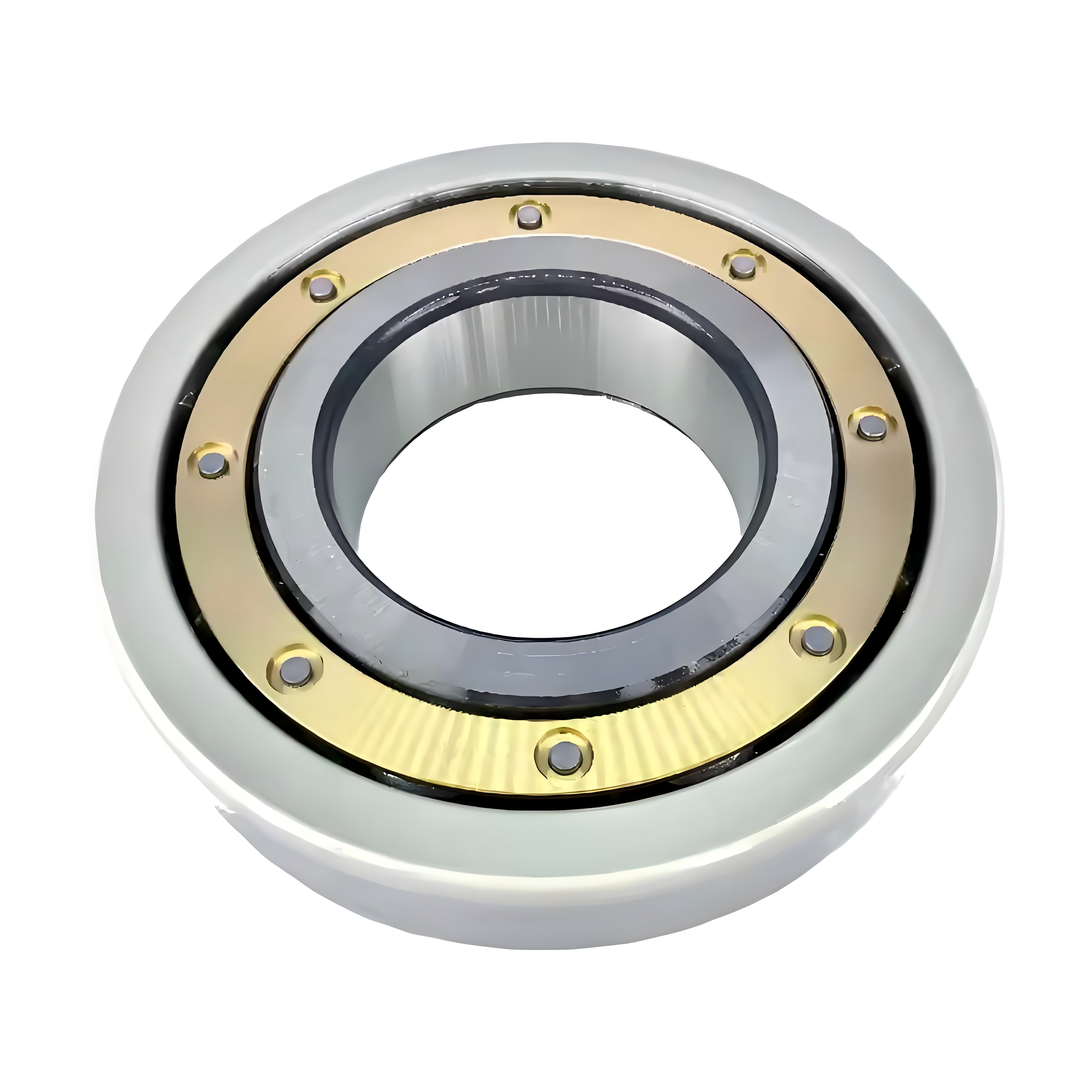

Electrically Insulated Bearings

The electrically insulated bearings use a special spraying process to spray a high-quality coating on the outer surface of the bearing. The coating has a strong bond with the substrate and good insulation performance, which can avoid the electro-corrosion of the bearing by the induced current, prevent the current from damaging the grease, rolling elements and raceways, and increase the service life of the bearing. The process is constantly being improved. In the insulated bearing, there is a 100μm thick coating on the outer or inner ring surface, which can withstand a voltage of up to 1000 V DC. The special spraying process can form a coating with uniform thickness and extremely strong adhesion, and after further treatment, it can be unaffected by moisture and humidity.

144 Results

| Model number | Basic size | Basic load rating | Rated speed | ||||

|---|---|---|---|---|---|---|---|

| Dynamic state | Static | Reference speed | Limiting speed | ||||

| d [mm] | D [mm] | B [mm] | C [kN] | C₀ [kN] | [r/min] | [r/min] | |

|

6330/C3VL2071

|

150 | 320 | 65 | ||||

|

6414M/C3VL2071

|

70 | 180 | 42 | ||||

|

6415M/C3VL2071

|

75 | 190 | 45 | ||||

|

6022M/C3VL2071

|

110 | 170 | 28 | ||||

|

6028M/C3VL2071

|

140 | 210 | 33 | ||||

|

6030M/C3VL2071

|

150 | 225 | 35 | ||||

|

6036M/C3VL2071

|

180 | 280 | 46 | ||||

|

6038/C3VL2071

|

190 | 290 | 46 | ||||

|

6215M/C3VL2071

|

70 | 130 | 25 | ||||

|

6216/C3VL2071

|

80 | 140 | 26 | ||||

|

6220M/C3VL2071

|

100 | 180 | 34 | ||||

|

6221M/C3VL2071

|

105 | 190 | 36 | ||||

| Model number | Basic size | Basic load rating | Rated speed | ||||

|---|---|---|---|---|---|---|---|

| Dynamic state | Static | Reference speed | Limiting speed | ||||

| d [in] | D [in] | B [in] | C [Ibf] | C₀ [Ibf] | [r/min] | [r/min] | |

|

6330/C3VL2071

|

|||||||

|

6414M/C3VL2071

|

|||||||

|

6415M/C3VL2071

|

|||||||

|

6022M/C3VL2071

|

|||||||

|

6028M/C3VL2071

|

|||||||

|

6030M/C3VL2071

|

|||||||

|

6036M/C3VL2071

|

|||||||

|

6038/C3VL2071

|

|||||||

|

6215M/C3VL2071

|

|||||||

|

6216/C3VL2071

|

|||||||

|

6220M/C3VL2071

|

|||||||

|

6221M/C3VL2071

|

|||||||

Product type, design and form

Ceramic bearings

This type of bearing uses ceramic rolling elements, has excellent wear resistance and insulation performance, and is suitable for high temperature and low friction environments.

Electrically insulated cylindrical roller bearings

It has a large radial load capacity and is suitable for occasions that withstand heavy loads and impact loads.

Electrically insulated angular contact ball bearings

This type of bearing can withstand radial and axial loads and is suitable for occasions that need to withstand both loads at the same time.

Electrically insulated deep groove ball bearings

This type of bearing has the characteristics of low friction coefficient, high limiting speed, and good insulation performance. It is suitable for occasions that require high speed and good insulation performance.

Advantage

1. Improve equipment reliability: Insulated bearings can isolate current and avoid the impact of current on bearings, thereby protecting the safe operation of equipment and ensuring long-term and stable operation of equipment, greatly improving the reliability of equipment

2. Extend equipment service life: The special materials and manufacturing process of insulated bearings make them more resistant to high temperature and corrosion, and can operate normally even in harsh environments, effectively extending the service life of equipment

3. Reduce maintenance costs: The use of insulated bearings can reduce equipment failures and maintenance times, reduce downtime and maintenance costs caused by bearing damage, and further reduce overall maintenance costs

4. Anti-electrocorrosion: The coating of the insulated bearing has good insulation properties, which can avoid the electrocorrosion of the induced current on the bearing, protect the bearing from damage by electrocorrosion, and thus extend the service life of the bearing.

5. Wear resistance: Some insulated bearings use ceramic rolling elements made of Si3N4 material, which have excellent wear resistance and low lubrication requirements. They are particularly suitable for high-speed, low-friction and low-temperature operation.

Application

The outer dimensions and basic technical characteristics of the insulated bearing are the same as those of the non-insulated bearing, and can be seamlessly replaced. They are widely used in motors, generators and other equipment, especially variable-frequency motors, to meet various work needs.

Implementation methods

Electrically insulated bearings can be implemented in various ways, mainly including the following:

1. Ceramic coating: Use high-hardness, wear-resistant ceramic oxide materials, such as alumina, and evenly coat them on the outer or inner ring surface of the bearing through advanced processes such as plasma spraying. The coating thickness is generally between 0.2mm and 0.4mm to ensure sufficient insulation strength and wear resistance.

2. Special PPS coating: Use PPS, a polymer material with excellent insulation properties, to form a dense insulation layer through improved formulation and process. This coating has excellent insulation and wear resistance, and can maintain stable electrical insulation performance in harsh environments.

3. Hybrid ceramic bearings: The rolling elements are made of ceramic materials (such as silicon nitride), and the inner and outer rings are made of bearing steel. This structure enables the bearing to have good electrical insulation performance while maintaining high strength and wear resistance.

4. Insulating bearing sleeve structure: Add a layer of insulating material on the basis of the outer or inner sleeve of the bearing to form an electrical insulation barrier. This structure is simple, easy to install and maintain, and is suitable for various occasions requiring electrical insulation.

+86-18615202650

+86-18615202650