Home > Product > Stainless Steel Bearing

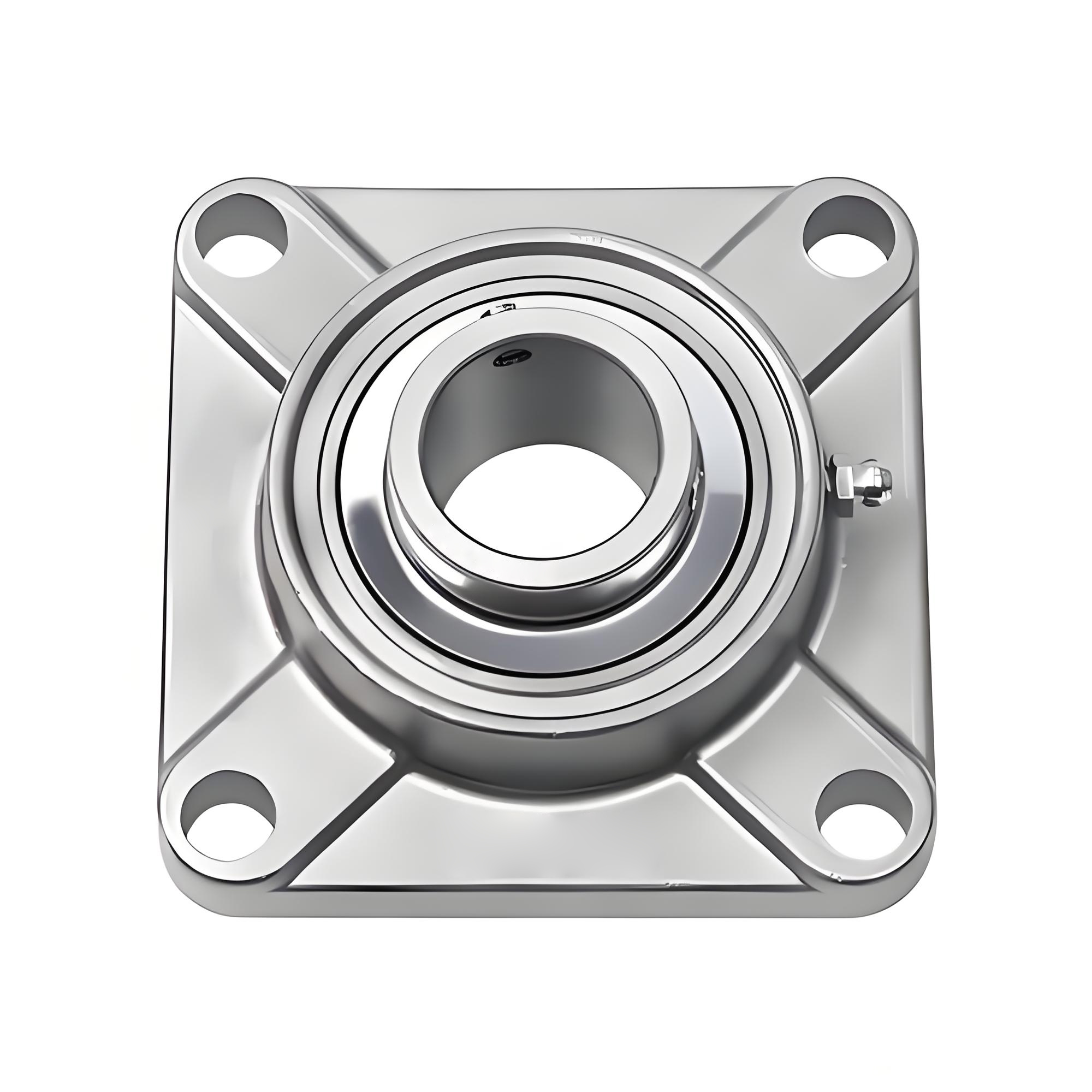

Stainless Steel Bearing

Stainless steel bearings can achieve high strength and high precision, and can be used in a variety of products that are prone to rust and strong corrosion, and have a wide range of uses. High-performance stainless steel bearings also achieve the same high precision and wear resistance as high-carbon chromium steel on the basis of corrosion resistance. The precision of TFL stainless steel bearings is higher than ISO standard ABEC-1, and the vibration level is Z1 group and above.

Stainless steel outer spherical bearings are usually used in harsh working environments such as soil, dust, humidity and high temperature, and are suitable for many applications such as metallurgy, mining, environmental protection, chemical industry, light industry, textile, food machinery, agricultural machinery, transportation systems or engineering machinery.

Design and variation

Product details

228 Results

| Model number | Basic size | Basic load rating | Rated speed | ||||

|---|---|---|---|---|---|---|---|

| Dynamic state | Static | Reference speed | Limiting speed | ||||

| d [mm] | D [mm] | B [mm] | C [kN] | C₀ [kN] | [r/min] | [r/min] | |

|

SS6008

|

40 | 68 | 15 | 14.25 | 9.22 | ||

|

SS6009 2RS

|

45 | 75 | 16 | 18.5 | 15 | ||

|

SS6009 2Z

|

45 | 75 | 16 | 18.2 | 15 | ||

|

SS6009

|

45 | 75 | 16 | 15.1 | 9.66 | ||

|

SS6010 2RS

|

50 | 80 | 16 | 19 | 16.6 | ||

|

SS6010 2Z

|

50 | 80 | 16 | 19 | 16.6 | ||

|

SS6010

|

50 | 80 | 16 | 18.5 | 13.2 | ||

|

SS6011

|

55 | 90 | 18 | 28.5 | 21.2 | ||

|

SS6012

|

60 | 95 | 18 | 29 | 23 | ||

|

SS6200 2RS

|

10 | 30 | 9 | 4.36 | 2.32 | ||

|

SS6200 2Z

|

10 | 30 | 9 | 4.36 | 2.92 | ||

|

SS6200

|

10 | 30 | 9 | 4.34 | 1.92 | ||

| Model number | Basic size | Basic load rating | Rated speed | ||||

|---|---|---|---|---|---|---|---|

| Dynamic state | Static | Reference speed | Limiting speed | ||||

| d [in] | D [in] | B [in] | C [Ibf] | C₀ [Ibf] | [r/min] | [r/min] | |

|

SS6008

|

|||||||

|

SS6009 2RS

|

|||||||

|

SS6009 2Z

|

|||||||

|

SS6009

|

|||||||

|

SS6010 2RS

|

|||||||

|

SS6010 2Z

|

|||||||

|

SS6010

|

|||||||

|

SS6011

|

|||||||

|

SS6012

|

|||||||

|

SS6200 2RS

|

|||||||

|

SS6200 2Z

|

|||||||

|

SS6200

|

|||||||

Product type, design and form

420 Stainless Steel Bearings

It has higher hardness and wear resistance, but its comprehensive performance is between 304 and 440C. 420 stainless steel bearings are suitable for general mechanical equipment and electrical equipment.

316 Stainless Steel Bearings

Molybdenum is added to 304 stainless steel to improve corrosion resistance, especially in marine and acidic environments. 316 stainless steel bearings also have good mechanical properties and toughness.

304 Stainless Steel Bearings

It is known for its excellent corrosion resistance and is widely used in industries such as food, medical and chemical. 304 stainless steel belongs to austenitic stainless steel, which is usually non-magnetic or weakly magnetic, with good mechanical strength and toughness.

440C Stainless Steel Bearings

This bearing is made of high-carbon stainless steel, with extremely high hardness and excellent wear resistance, suitable for use in high-load and high-friction environments. However, its corrosion resistance is relatively poor, but it can still resist corrosion from a variety of chemicals.

Advantage & Application

1. Corrosion resistance: Stainless steel bearings are not easy to rust and have strong corrosion resistance. AISI 316 stainless steel can even run in liquid without lubrication.

2. High strength and high precision: Stainless steel bearings have high mechanical strength and strong load-bearing capacity, and are suitable for occasions such as food processing, medical equipment and pharmaceutical machinery that require high precision and high wear resistance.

3. Stable operation: Stainless steel bearings have low noise and good stability during operation, and are suitable for various harsh working environments such as soil, dust, humidity and high temperature.

When choosing stainless steel bearings, it is necessary to comprehensively consider factors such as material hardness, wear resistance, corrosion resistance and cost according to specific application scenarios and needs.

+86-18615202650

+86-18615202650