Home > Product > Tapered Roller Bearing

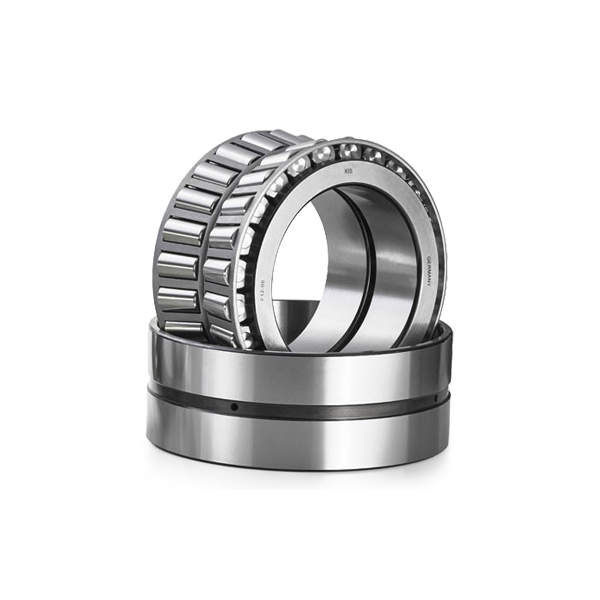

Tapered Roller Bearing

Tapered roller bearings are radial thrust rolling bearings whose rolling elements are tapered rollers. There are two types: small taper angle and large taper angle. Small taper angle mainly bears radial and axial combined loads, mainly radial loads. They are often used in pairs and installed in reverse. The inner and outer races can be installed separately. The radial and axial clearances can be adjusted during installation and use. Large taper angle mainly bears axial and radial combined loads, mainly axial loads. They are generally not used alone to bear pure axial loads. When they are configured in pairs (with the same end installed opposite to each other), they can be used to bear pure radial loads.

Design and variation

Product details

415 Results

| Model number | Basic size | Basic load rating | Rated speed | ||||

|---|---|---|---|---|---|---|---|

| Dynamic state | Static | Reference speed | Limiting speed | ||||

| d [mm] | D [mm] | B [mm] | C [kN] | C₀ [kN] | [r/min] | [r/min] | |

|

30214

|

70 | 125 | 26.5 | 132 | 175 | 3800 | 3000 |

|

30216

|

80 | 140 | 28.5 | 160 | 212 | 3400 | 2600 |

|

30215

|

75 | 130 | 27.5 | 138 | 185 | 3600 | 2800 |

|

30217

|

85 | 150 | 31 | 178 | 238 | 3200 | 2400 |

|

30218

|

90 | 160 | 33 | 200 | 270 | 3000 | 2200 |

|

30219

|

95 | 170 | 35 | 228 | 308 | 2800 | 2000 |

|

30220

|

100 | 180 | 37.5 | 255 | 350 | 2600 | 1900 |

|

30221

|

105 | 190 | 39.5 | 285 | 398 | 2400 | 1800 |

|

30222

|

110 | 200 | 41.5 | 315 | 445 | 2200 | 1700 |

|

30314

|

70 | 150 | 38.5 | 218 | 272 | 3400 | 2600 |

|

30313

|

65 | 140 | 36.5 | 195 | 242 | 3600 | 2800 |

|

30312

|

60 | 130 | 34 | 170 | 210 | 4000 | 3200 |

| Model number | Basic size | Basic load rating | Rated speed | ||||

|---|---|---|---|---|---|---|---|

| Dynamic state | Static | Reference speed | Limiting speed | ||||

| d [in] | D [in] | B [in] | C [Ibf] | C₀ [Ibf] | [r/min] | [r/min] | |

|

30214

|

3800 | 3000 | |||||

|

30216

|

3400 | 2600 | |||||

|

30215

|

3600 | 2800 | |||||

|

30217

|

3200 | 2400 | |||||

|

30218

|

3000 | 2200 | |||||

|

30219

|

2800 | 2000 | |||||

|

30220

|

2600 | 1900 | |||||

|

30221

|

2400 | 1800 | |||||

|

30222

|

2200 | 1700 | |||||

|

30314

|

3400 | 2600 | |||||

|

30313

|

3600 | 2800 | |||||

|

30312

|

4000 | 3200 | |||||

Product Type

Four-row tapered roller bearings

The performance of the four-row tapered roller bearing is basically the same as that of the double-row tapered roller bearing, but the load-bearing capacity is greater and it is suitable for heavy machinery such as rolling mills.

Double row tapered roller bearings

Double-row tapered roller bearings can bear bidirectional axial loads and radial loads at the same time, and are suitable for situations where bidirectional axial movement of the shaft or housing needs to be restricted.

Single row tapered roller bearings

Tapered roller bearings can only bear axial loads in one direction and are suitable for situations where the unidirectional axial displacement of the shaft or housing needs to be limited.

Characteristics and advantages

1. High load capacity: Tapered roller bearings can operate stably under heavy loads and impact loads, and are ideal for heavy loads. They are

widely used in rolling mills, cranes, mining equipment and other occasions.

2. Self-aligning performance: This type of bearing has good self-aligning performance and can automatically adjust the axis deviation to make

the bearing force uniform, reduce wear and fatigue, and extend the service life.

3. High temperature resistance: The use of high temperature resistant materials and grease can operate stably in high temperature environments,

and is suitable for high temperature industrial fields such as hot rolling mills, hot forging machines, and heat treatment equipment.

4. Strong adaptability: It is suitable for various types of mechanical transmission systems, such as rotation, sliding, rolling, etc., and is also suitable

for various installation methods, such as face-to-face, back-to-back, and series.

5. High reliability: It adopts precision processing and strict quality control, has good reliability and stability, and reduces failures and maintenance costs.

6. Easy maintenance: The design makes maintenance and replacement simple and convenient. Most tapered roller bearings can be installed and removed

from the side or end surface without disassembling the entire transmission system.

Application fields:

Tapered roller bearings are widely used in automobiles, aerospace, mining machinery and other fields. In automobile transmission systems, they can

withstand a large amount of axial and radial loads to ensure the stability and reliability of the transmission system; in aerospace equipment, they need

to withstand huge axial and radial loads and have extremely high speed and precision requirements; in mining machinery and equipment, due to the

harsh working environment and heavy loads, tapered roller bearings have become indispensable components due to their high load-bearing capacity

and stability.

+86-18615202650

+86-18615202650